CNC machine tools (Computer Numerical Control Machine Tool) are a modern mechanical processing equipment widely used in industries such as automobiles, aerospace, precision molds, and medical devices. It drives mechanical parts to complete cutting, drilling, milling and other processes through precise instructions from the computer control system, and can efficiently produce high-precision complex parts. This article will quickly introduce you to the definition, working principle and application fields of CNC machine tools to help you fully understand this important industrial equipment.

Definition of CNC machine tools

CNC machine tools are machine tools that use computer numerical control technology for automated control. Compared with traditional manual machine tools, CNC machine tools use computer control systems and actuators (such as servo motors and drive systems) to accurately adjust the machine tool motion trajectory and tool path, thereby achieving high-precision and high-efficiency parts processing.

By inputting instructions through G code (CNC program), CNC machine tools can perform simple cutting to complex multi-axis linkage processing, greatly improving production accuracy, processing efficiency and flexibility.

Working principle of CNC machine tools

The working principle of CNC machine tools mainly depends on the computer control system, which parses the input program (G code) into precise control signals that the machine can execute, and then drives the moving parts of the machine tool to process according to the set trajectory.

1. Input of CNC program

The operator designs the part drawings through CAD/CAM software and generates CNC programs. The program content includes information such as tool path, feed speed, cutting depth, etc., which are written in G code and transmitted to the CNC system.

2. Analysis and control of CNC system

After receiving the program, the CNC control system is responsible for parsing these G codes and converting them into machine motion instructions. It will control the movement speed, direction and feed amount of the machine tool according to the program content, and accurately mobilize each axis and spindle for processing.

3. Servo system drive and execution

The CNC system controls the movement of the machine tool through servo motors. The servo drive system achieves high-speed and high-precision movement through real-time feedback control to ensure the precise positioning of each component of the machine tool.

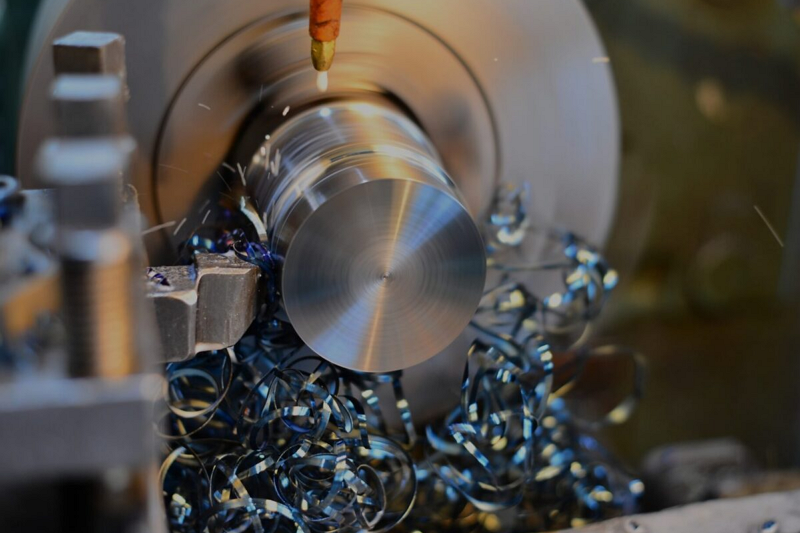

4. Processing process

The machine tool follows the instructions of the CNC system, and the tool performs cutting along the predetermined path. During the entire processing process, every movement of the machine tool is precisely controlled, which is why CNC machine tools can process high-precision, complex-shaped parts.

![CNC Machine Tools manufacturer1 CNC Machine Tools manufacturer1]()

Core advantages of CNC machine tools

High precision: Due to the use of computer automatic control, the processing accuracy of CNC machine tools is much higher than that of traditional machine tools, which can meet the needs of high-end manufacturing.

High efficiency: CNC machine tools can realize automated operation, reduce manual intervention and errors, and improve production efficiency.

Complex shape processing: The multi-axis linkage system enables CNC machine tools to process complex geometric shapes and surfaces without being restricted by the complexity of the workpiece.

Stability and consistency: CNC machine tools can maintain consistency in processing quality under long-term, high-load working conditions, which is very suitable for mass production.

Flexibility: The processing parameters can be changed through programming, so that CNC machine tools can quickly switch to different processing tasks and adapt to small batch and multi-variety production.

Application fields of CNC machine tools

CNC machine tools are widely used in many industries. The following are some typical application fields:

1. Automobile manufacturing

CNC machine tools are widely used in the automotive industry, mainly for the processing of engine parts, body parts and molds. Its precision and processing capabilities ensure the efficient production of automotive parts under high precision requirements.

2. Aerospace

In the aerospace industry, CNC machine tools are used to produce aircraft parts, spacecraft parts and precision instruments. Parts require strict dimensional tolerances and material strength, and CNC machine tools are the ideal tools to meet these high standards.

3. Precision mold manufacturing

The mold industry has very high requirements for precision, especially injection molds, stamping molds, etc. CNC machine tools can process extremely precise mold parts to ensure the stability and efficiency of molds in long-term use.

4. Medical devices

The application of CNC machine tools in the field of medical devices is also growing, especially in the manufacturing process of precision parts such as surgical tools, implants, etc. The high precision of CNC processing ensures the safety and reliability of medical devices.

5. Metal processing and tool manufacturing

The metal processing industry relies on CNC machine tools to complete metal cutting, milling and other processing tasks, especially the manufacture of precision tools and cutting tools.

Future Outlook: Intelligence and Automation

With the rise of intelligent manufacturing and Industry 4.0, CNC machine tools will develop in a more intelligent direction. In the future, CNC machine tools will pay more attention to integration with production systems, remote monitoring, data analysis and automated operations. Through the combination of artificial intelligence, big data analysis and Internet of Things technology, the production efficiency, intelligent scheduling and fault warning functions of CNC machine tools will be further improved, promoting the development of manufacturing industry towards digitalization and intelligence.

![Moving Crossbeam 5-axis Simultaneous (Dual Head) CNC Gantry Machining Center.jpg]()

![Moving Crossbeam CNC Gantry Machining Center.jpg]()

![High-Speed Gantry Milling Center for Extra Long Jobs in Aerospace.jpg]()

![Moving Crossbeam CNC Gantry Milling Machining Center.jpg]()

![Heavy Cutting Movable Column CNC Machining Center Series.jpg]()

![未命名圖片 (5).jpg]()

![CNC Moving Column Milling Center.jpg]()

![High-Speed Series for Mould Machining.jpg]()

![CNC Vertical Milling Machining Center.jpg]()

![CNC Horizontal Milling Machining Center.jpg]()